CENTRIFUGAL CASTING

In centrifugal casting process, molten metal is poured into a revolving mold and allowed to solidify molten metal by pressure of centrifugal force. It is employed for mass production of circular casting as the castings produced by this process are free from impurities. Due to centrifugal force, the castings produced will be of high density type and of good strength. The castings produced promote directional solidification as the colder metal (less temperature molten metal) is thrown to outside of casting and molten metal near the axis or rotation. The cylindrical parts and pipes for handling gases are most adoptable to this process. Centrifugal casting processes are mainly of three types which are discussed as under.

(1) True centrifugal casting

(2) Semi-centrifugal casting and

(3) Centrifuged casting

True Centriugal Casting

In true centrifugal casting process, the axis of rotation of mold can be horizontal, vertical or inclined. Usually it is horizontal. The most commonly articles which are produced by this process are cast iron pipes, liners, bushes and cylinder barrels. This process does not require any core. Also no gates and risers are used. Generally pipes are made by the method of the centrifugal casting. The two processes namely De Lavaud casting process and Moore casting process are commonly used in true centrifugal casting. The same are discussed as under:

De Levaud Casting Process

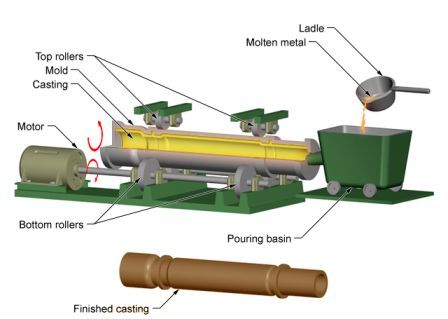

Fig shows the essential components of De Levaud type true centrifugal casting process. The article produced by this process is shown in Fig. In this process, metal molds prove to be economical when large numbers of castings are produced. This process makes use of metal mold. The process setup contains an accurately machined metal mold or die surrounded by cooling water. The machine is mounted on wheels and it can be move lengthwise on a straight on a slightly inclined track. At one end of the track there is a ladle

containing proper quantities of molten metal which flows a long pouring spout initially inserted to the extremity of the mold. As pouring proceeds the rotating mold, in the casting machine is moved slowly down the track so that the metal is laid progressively along the length of the mold wall flowing a helical path. The control is being achieved by synchronizing the rate of pouring, mold travel and speed of mold rotation. After completion of pouring the machine will be at the lower end of its track with the mold that rotating continuously till the molten metal has solidified in form of a pipe. The solidified casting in form of pipe is extracted from the metal mold by inserting a pipe puller which expands as it is pulled.

Moore Casting System

Moore casting system for small production of large cast iron pipes employs a ram and dried sand lining in conjunction with end pouring. As the mold rotates, it does not move lengthwise rather its one end can be raised up or lowered to facilitate progressive liquid metal. Initially one end of the mold is raised as that mold axis gets inclined. As the pouring starts and continues, the end is gradually lowered till the mold is horizontal and when the pouring stops. At this stage, the speed of mold rotation is increased and maintained till the casting is solidified. Finally, the mold rotation is stopped and the casting is extracted from the mold.

Semi-Centrifugal Casting

It is similar to true centrifugal casting but only with a difference that a central core is used to form the inner surface. Semi- centrifugal casting setup is shown in Fig. This casting process is generally used for articles which are more complicated than those possible in true centrifugal casting, but are axi-symmetric in nature. A particular shape of the casting is produced by mold and core and not by centrifugal force. The centrifugal force aids proper feeding and helps in producing the castings free from porosity. The article produced by this process is shown in Fig. Symmetrical objects namely wheel having arms like flywheel, gears and back wheels are produced by this process.

Centrifuging Casting

Centrifuging casting setup is shown in Fig. This casting process is generally used for producing non-symmetrical small castings having intricate details. A number of such small jobs are joined together by means of a common radial runner with a central sprue on a table which is possible in a vertical direction of mold rotation. The sample article produced by this process is depicted in Fig. Copied from A Basic Manufacturing Processes and Workshop Technology by Rajender Singh.