DESIGN AND FABRICATION OF PLATE FREEZER

ABSTRACT

Techniques of freezing vary for each application, The type of refrigeration used for preserving fruits cannot suit the need of the fish industries. Later it has been discovered that the number of viable vegetative microorganisms in food are usually greatly reduced by freezing if quick freezing is employed. The conventional freezers could not cope with this higher rate of freezing. By the development of the plate freezer, the challenge of quick freezing has been met to enhance effective preservation.

Plate type evaporators may be used in single or in banks. The plates may be manifolds for parallel flow of the refrigerant or they may be connected for series flow. Plate evaporators are especially useful used for liquid cooling installation where unusual peak load conditions are encountered periodically.

In the present work, a plate freezer consisting of two plates connected in parallel and having a cooling load of 0.335 KW is to be designed. Installing formed tubing between two metal plates, which are brazed together at the edges, forms the plate surface evaporators.

The refrigerant used is R-134a a refrigerant which is now used as a replacement for R-12.

INTRODUCTION

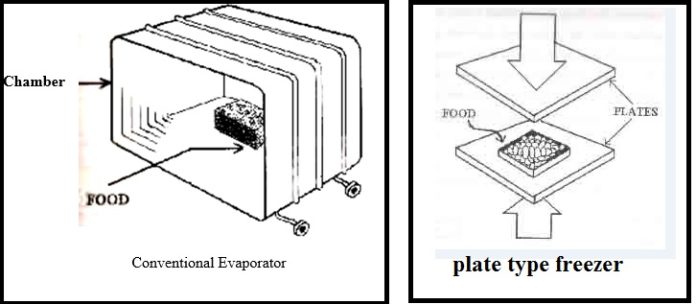

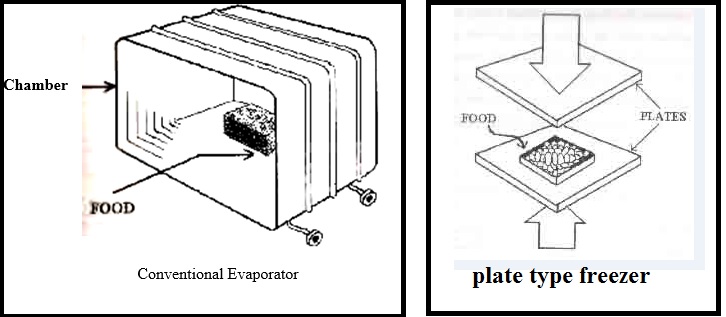

Conventional food preservation is done by keeping the food inside chambers having evaporator coils around it. This chamber is insulated from the surroundings by a casing. The vapour compression system is the most widely used system.

The heat transfer takes place from the food to the freezer (chamber) surface through the air gap. As air is a bad conductor of heat, the freezing rate is low and time consuming. The freezing rate was increased by the development of the freezer. Only compactable foods can utilize this method.

The Plate freezer under consideration is a multi plate freezer. In the plate freezer there are two plates through which the refrigerant expands. The food is placed between the plates and are brought closer so that the food gets pressed to a pre-determined pressure. As the plates are in direct contact with the food, there is better heat transfer and hence the freezing rate is increased.

The plate used is copper plate, which is having a high heat transfer coefficient. The two plates are brought closer manually.

Compared to the conventional method of freezing this method takes only a Quarter of the time required to bring 1 kg of meat from 30 ºC to -20 ºC, the freezing rate is increased about four times. This is the most important reason why plate freezers are replacing conventional freezing equipments in the recent past.