ARC WELDING PROCESSES

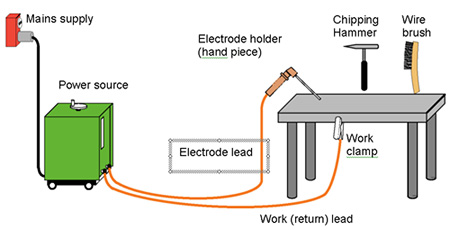

The process, in which an electric arc between an electrode and a workpiece or between two electrodes is utilized to weld base metals, is called an arc welding process. The basic principle of arc welding is shown in Fig. However the basic elements involved in arc welding process are shown in Fig. Most of these processes use some shielding gas while others employ coatings or fluxes to prevent the weld pool from the surrounding atmosphere. The various arc welding processes are:

1. Carbon Arc Welding

2. Shielded Metal Arc Welding

3. Flux Cored Arc Welding

4. Gas Tungsten Arc Welding

5. Gas Metal Arc Welding

6. Plasma Arc Welding

7. Atomic Hydrogen Welding

8. Electroslag Welding

9. Stud Arc Welding

10. Electrogas Welding

Arc Welding Equipment

Arc welding equipment, setup and related tools and accessories are shown in Fig. However some common tools of arc welding are shown separately through Fig.

Few of the important components of arc welding setup are described as under.

1. Arc welding power source

Both direct current (DC) and alternating current (AC) are used for electric arc welding, each having its particular applications. DC welding supply is usually obtained from generators driven by electric motor or if no electricity is available by internal combustion engines. For AC welding supply, transformers are predominantly used for almost all arc welding where mains electricity supply is available. They have to step down the usual supply voltage (200- 400 volts) to the normal open circuit welding voltage (50-90 volts). The following factors influence the selection of a power source:

1. Type of electrodes to be used and metals to be welded

2. Available power source (AC or DC)

3. Required output

4. Duty cycle

5. Efficiency

6. Initial costs and running costs

7. Available floor space

8. Versatility of equipment

2. Welding cables

Welding cables are required for conduction of current from the power source through the electrode holder, the arc, the workpiece and back to the welding power source. These are

insulated copper or aluminium cables.

3. Electrode holder

Electrode holder is used for holding the electrode mannually and conducting current to it. These are usually matched to the size of the lead, which in turn matched to the amperage

output of the arc welder. Electrode holders are available in sizes that range from 150 to 500 Amps.

4. Welding Electrodes

An electrode is a piece of wire or a rod of a metal or alloy, with or without coatings. An arc is set up between electrode and workpiece. Welding electrodes are classified into following types-

(1) Consumable Electrodes

(a) Bare Electrodes

(b) Coated Electrodes

(2) Non-consumable Electrodes

(a) Carbon or Graphite Electrodes

(b) Tungsten Electrodes

Consumable electrode is made of different metals and their alloys. The end of this electrode starts melting when arc is struck between the electrode and workpiece. Thus consumable electrode itself acts as a filler metal. Bare electrodes consist of a metal or alloy wire without any flux coating on them. Coated electrodes have flux coating which starts melting as soon as an electric arc is struck. This coating on melting performs many functions like prevention of joint from atmospheric contamination, arc stabilizers etc.

Non-consumable electrodes are made up of high melting point materials like carbon, pure tungsten or alloy tungsten etc. These electrodes do not melt away during welding. But practically, the electrode length goes on decreasing with the passage of time, because of oxidation and vaporization of the electrode material during welding. The materials of nonconsumable electrodes are usually copper coated carbon or graphite, pure tungsten, thoriated or zirconiated tungsten.

5. Hand Screen

Hand screen (Fig.) used for protection of eyes and supervision of weld bead.

6. Chipping hammer

Chipping Hammer (Fig.) is used to remove the slag by striking.

7. Wire brush

Wire brush (Fig.) is used to clean the surface to be weld.

8. Protective clothing

Operator wears the protective clothing such as apron to keep away the exposure of direct heat to the body. Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Songh.