WIRE DRAWING

The wire drawing die setup is shown in Fig. The process of producing the wires of different diameters is accomplished

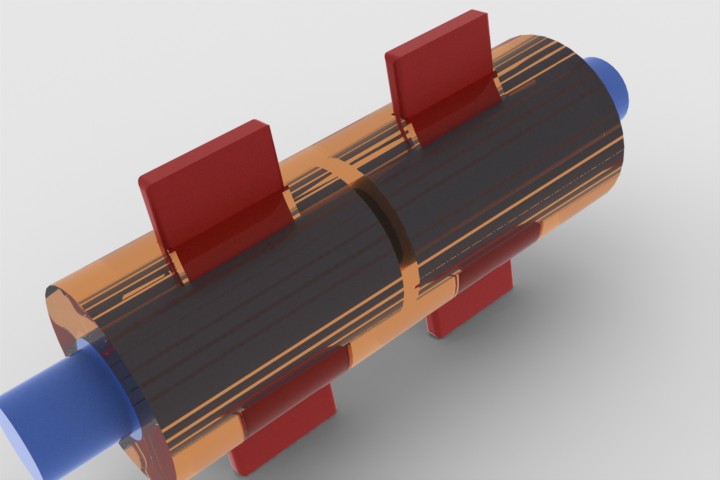

by pulling a wire through a hardened die usually made up carbide. However a smaller diameter wires are drawn through a die made of diamond. The larger diameter oriented wire is first cleaned, pickled, washed and then lubricated. Cleaning is essentially done to remove any scale and rust present on the surface, which may severely affect the die. It is normally done by acid pickling. The hot rolled steel is descaled, pickled in acid, washed in water and coated with lime and other lubricants. To make for an easier entrance of wire into the die, the end of the stock is made pointed to facilitate the entry. A pointed or reduced diameter at the end of wire duly lubricated is pushed or introduced through the die which is water cooled also. This pointing is done by means of rotary swaging or by simple hammering.

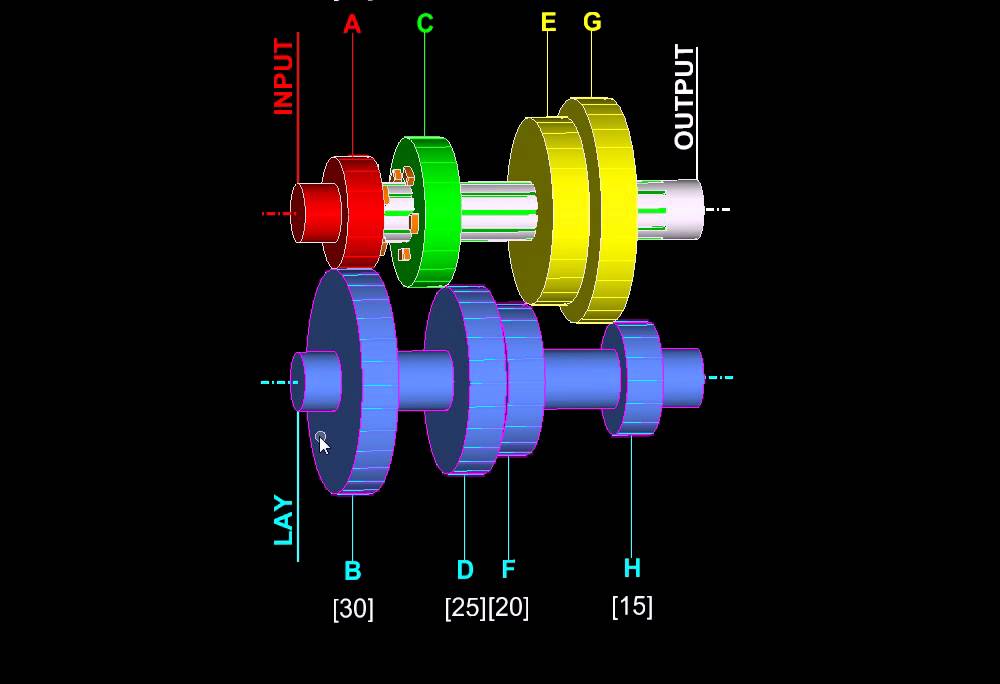

It is then gripped and pulled for attaching it to a power driven reel. The wire diameter is reduced in die because of the ductility property of the material to the smaller diameter through one set of die. However for more reduction in diameter of the wire, various sets of dies can be used in line for subsequent reduction in diameter at each stage as shown in Fig. The reduction in each pass through the die range about 10% for steel and 40% for ductile materials such as copper. The drawing of the wire starts with a rod or coil of hot rolled steel, which is 0.8 to 1.6 mm larger than the final size required. In this process, there is no force is applied for pushing the wire into the die from the entrance side. The material should be sufficiently ductile since it is pulled by the tensile forces. Hence, the wire may have to be annealed properly to provide the necessary ductility. Further, the wire is to go through the conical portion and then pulled out through the exit by the gripper. The other aspect of preparation needed is the cleaning of the wire and lubricating it as it flows through the die. The pressures acting at the interface of the die and the metal being very high, the lubrication of the die is a serious problem.

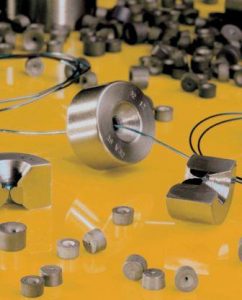

Therefore, to carry the lubricant through the die, special methods such as gulling, coppering, phosphating and liming are used. The wire is coated with a thin coat of ferrous hydroxide which when combined with lime acts as filler for the lubricant. This process is called sulling. In phosphating, a thin film of manganese, iron or zinc phosphate is applied on the wire, which makes the lubricant to stick to the wire, thereby reducing the friction and consequently, the drawing load. Another lubricant vehicle that is used in wire drawing is a coating of lime. After acid pickling, lime is applied and then allowed to dry. The lime neutralizes any amount of acid left on the surface and adsorbs the lubricant for carrying it to the die. The lubricant normally used is the soap solution. For very thin wires, electrolytic coating of copper is used to reduce friction. The dies used for wire drawing are severely affected because of high stresses and abrasion. The various die materials that are used are chilled cast iron, tool steels, tungsten carbide and diamond. The cast iron dies are used for small runs. For very large sizes, alloy steels are used in making the dies. The tungsten carbide dies are used most commonly for medium size wires and large productions. The tungsten carbide dies are referred because of their long life that is 2 to 3 times that of alloy steel dies. For very fine wires, diamond dies are used. Wire drawing improves the mechanical properties because of the cold working. The material loses its ductility during the wire drawing process and when it is to be repeatedly drawn to bring it to the final size, intermediate annealing is required to restore the ductility. Source A Textbook of Manufacturing Processes and Workshop Technology by Rajender Singh.