Resistance Upset Butt and Flash Butt Welding

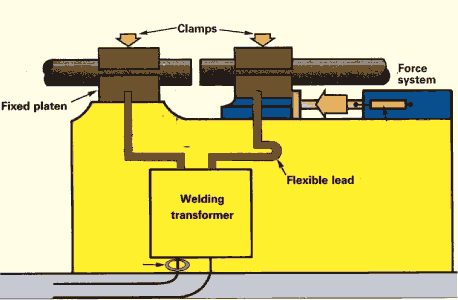

This welding is also used for joining metal pieces end to end but it has largely replaced the butt-welding method for weld articles small cross-sections. It can be used for thick sections also. Initially the current is switched on and then one end the moveable part to be welded is brought gently closer to the fixed end of the other part to localize heat at the ends and thus raises the temperature of the ends quickly to the welding heat. On acquiring contact of fixed end and moveable end with each other, the moveable end is then pressed against one another by applying mechanical pressure. Thus the molten metal and slag to be squeezed out in the form of sparks enabling the pure metal to form the joint and disallowing the heat .to spread back. The principle of upset butt welding and flash butt welding are depicted in Fig. In this resistance welding single phase A.C. machines are commonly employed. The merits and demerit of flash welding over simple butt-welding are follows:

Merits

1. It is comparatively much faster than butt welding.

2. This method utilizes less current in comparison to butt welding as the small portion of the metal is only being heated for getting a good weld.

3. Created joint by this welding is much stronger than the butt welding joint. Also the strength of the weld produced is high even more than that of the base metal. The end of the metal pieces to be welded in this welding need not be squared as it is the basic requirement in butt-welding.

4. A high degree of accuracy can be easily achieved in terms of length alignment of weld.

Demerits

1. The periodic maintenance of machine and replacement of insulation is needed as flashing particles of molten metal are thrown out during welding which may enter into the slide ways and insulation of the set up.

2. Welder has to take enough care against possible fire hazard due to flashing during welding.

3. Additional stock has to be provided for compensating loss of metal during flashing and upsetting. This increases to the cost of weld.

4. Cost of removal of flash weld metal by trimming, chipping, grinding, etc. will increase to the welded product.

5. Surface of the jobs where they come in contact with the gripping surfaces, should be clean otherwise they will restrict the flow of electric current.

6. The available power, opening between the jaws of the gripping clamps and upsetting pressure of the welding set limit the size and cross sectional area of the jobs to be welded.

Applications

All conducting forged metals can be easily be flash welded. A number of dissimilar metals can also be welded by controlling the welding conditions carefully. Metals generally welded metal by the process involves lead, tin, antimony, zinc, bismuth and their alloys, low carbon steels, stainless steel, alloy steels, tool steels, copper alloys, aluminium alloys, magnesium alloys nickel alloys, molybdenum alloys, and titanium alloys. This process is used in automobile industry, welding of solid and tubular structural assemblies, etc. in air-craft industry, welding of band saw blades, welding of tool steel drills, reamers and taps etc. to mild steel or alloy steel shanks, welding of pipes and tubes.

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.