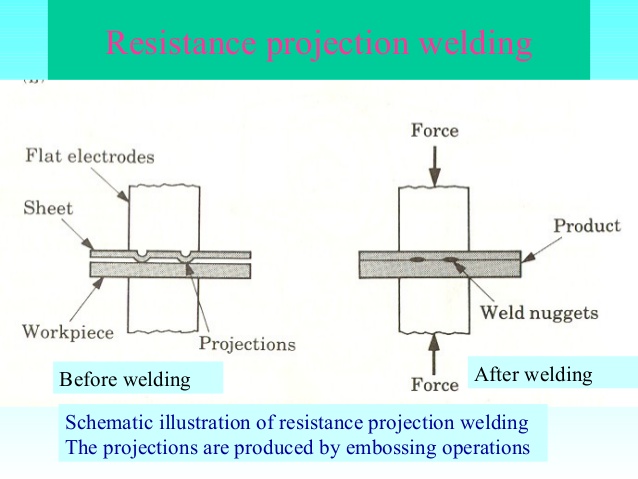

Resistance Projection Welding

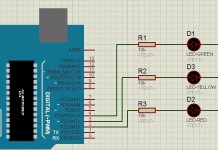

Fig. shows the projection welding. This process is a resistance welding process in which two or more than two spot welds are made simultaneously by making raised portions or projections on predetermined locations on one of the workpiece. These projections act to localize the heat of the welding circuit. The pieces to be welded are held in position under pressure being maintained by electrodes. The

projected contact spot for welding should be approximately equal to the weld metal thickness. The welding of a nut on the automotive chasis is an example of projection welding.

Like so many others, the resistance welding industry has seen an unprecedented rate of change in the last few years. The development of new types of steels and other materials, innovations in product designs, new coatings and new technologies are aimed at addressing ever increasing demands in occupant safety, quality and challenging component weight targets. Many of these changes have had a substantial impact on the projection welding of fasteners. Resistance welding in general relies on the precise control of current, force and time to create a weld using resistive heating. In some regards it is a “hot forging” process. In spot welding applications, there are a number of methods employed to monitor, control and react to normal variations in the process, materials and equipment conditions. Generally these strategies leverage the fact that spot welding is a slower and much less dynamic process as compared to projection welding. Although both processes are resistance welding, in projection welding, there is very little time to deal with variations since cycle times are dictated, in large part, by the rate of collapse of the projections. Slowing the process down has an effect on the heat that is needed for the weld. Additionally, once the projections are collapsed, further heating is detrimental to the weld. Ultimately, these two issues are the controlling factors in the times used in the set up of the weld schedule. Projection welding is a very dynamic process. As projections collapse, this triggers effects in both the force and the weld current profiles. The total weld may be as short as 10 ms and the collapse portion may be as little as 5-6 ms. In that time the welding machine is expected to “follow up” the typical 0.5 – 1.0 mm of the projection height – while still maintaining the weld force.

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.