MERITS OF HOT WORKING

1. As the material is above the recrystallisation temperature, any amount of working can be imparted since there is no strain hardening taking place.

2. At a high temperature, the material would have higher amount of ductility and therefore there is no limit on the amount of hot working that can be done on a material. Even brittle materials can be hot worked.

3. In hot working process, the grain structure of the metal is refined and thus mechanical properties improved.

4. Porosity of the metal is considerably minimized.

5. If process is properly carried out, hot work does not affect tensile strength, hardness, corrosion resistance, etc.

6. Since the shear stress gets reduced at higher temperatures, this process requires much less force to achieve the necessary deformation.

7. It is possible to continuously reform the grains in metal working and if the temperature and rate of working are properly controlled, a very favorable grain size could be achieved giving rise to better mechanical properties.

8. Larger deformation can be accomplished more rapidly as the metal is in plastic state.

9. No residual stresses are introduced in the metal due to hot working.

10. Concentrated impurities, if any in the metal are disintegrated and distributed throughout the metal.

11. Mechanical properties, especially elongation, reduction of area and izod values are improved, but fibre and directional properties are produced.

12. Hot work promotes uniformity of material by facilitating diffusion of alloy constituents and breaks up brittle films of hard constituents or impurity namely cementite in steel.

DEMERITS OF HOT WORKING

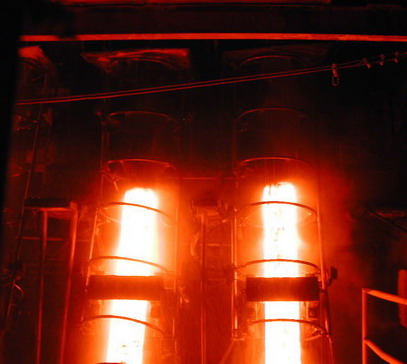

1. Due to high temperature in hot working, rapid oxidation or scale formation and surface de-carburization take place on the metal surface leading to poor surface finish and loss of metal.

2. On account of the loss of carbon from the surface of the steel piece being worked the surface layer loses its strength. This is a major disadvantage when the part is put to service.

3. The weakening of the surface layer may give rise to a fatigue crack which may ultimately result in fatigue failure of the component.

4. Some metals cannot be hot worked because of their brittleness at high temperatures.

5. Because of the thermal expansion of metals, the dimensional accuracy in hot working is difficult to achieve.

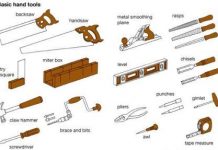

6. The process involves excessive expenditure on account of high cost of tooling. This however is compensated by the high production rate and better quality of components.

7. Handling and maintaining of hot working setups is difficult and troublesome. Source Introduction of a Basic Manufacturing Processes and Workshop Technology by Rajender Singh.