MECHANIZATION AND AUTOMATION

Mechanization means something is done or operated by machinery and not by hand. Mechanization of the manufacturing means is milestone oriented trend towards minimizing the human efforts to the extent of its possibility, by adopting mechanical and electrical means or methods for automating the different manufacturing processes. Such a trend may be in the area of automating and mechanizing the processes of material handling, loading and unloading of components, actual operations performed on the job or transportation, etc. But, no feedback is provided by the process, operation or machinery. Extension of mechanization of the production process is termed as automation and it is controlled by a closed loop system in which feedback is provided by the sensors. It controls the operations of different machines automatically. The automatic control may be applied for some operations or for all the operations of a machine or group of machines. Accordingly the machine will be known as semi-automatic or fully automatic. The term was identified shortly after the World War II at the Ford Motor Company to describe the automatic handling of materials and parts between the process operations.

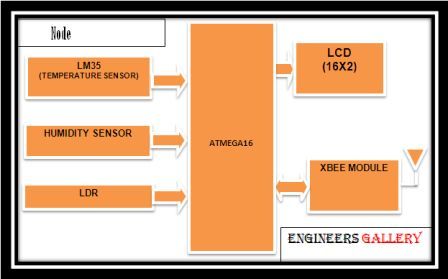

The word ‘automation’ is derived from the Greek word automatos meaning self-acting. Automation can also be defined as the process of following a predetermined sequence of operations with little or no human intervention, using specialized equipment and devices that perform and control the manufacturing process. Automation is a word that has many meanings in the industry today. Automatic machines of all kinds existed long before the term automation was conceived. But, it should be noted that all automatic machines do not come under the category of automation. Automation is a technology concerned with the application mechanical, electronic, and computer based systems to operate and control production. Every machine should involve some automation, may be to a lesser degree or to a higher extent to which is mainly governed by economic considerations. Automation means a system in which many or all of the processes in the production, movement, and inspection of parts and material are performed under control by the self-operating devices called controllers. This implies that the essential elements of automation comprise of mechanization, sensing, feedback, and control devices. The reasons why one should go for automation are:

1. Increased productivity

2. Reduced cost of labor and dependence on labor shortages

3. Improved quality

4. Reduced in-process inventory

5. Reduced manufacturing time

6. Reduced dependence on operator skills

7. Increased safety or reduced risk of humans.

Automation can be classified into three categories, viz.

1. Fixed automation

2. Programmable automation

3. Flexible automation.

1.10.1 Fixed Automation

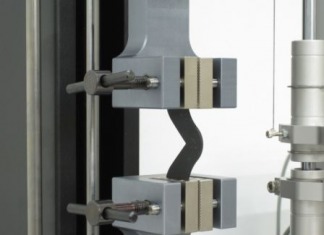

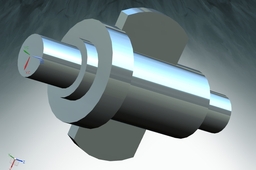

It is also known as hard automation which is utilized to produce a standardized product such as gears, nuts and bolts, etc. Even though the operating conditions can be changed, fixed automation is used for very large quantity production of one or few marginally different components. Highly specialized tools, devices, equipment, special purpose machine tools, are utilized to produce a product or a component of a product very efficiently and at high production rates with as low unit costs as possible relative to other alternative methods of manufacturing.

1.10.2 Programmable Automation

In programmable automation, one can change the design of the product or even change the product by changing the program. Such technique is highly useful for the low quantity production of large number of different components. The equipments used for the manufacturing are designed to be flexible or programmable. The production normally carried out in batches.

1.10.3 Flexible Automation

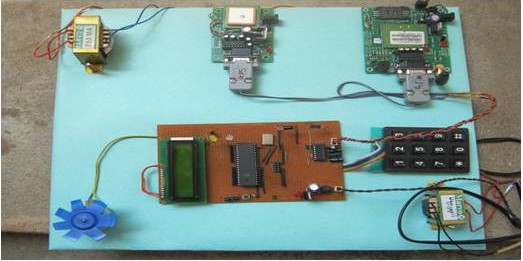

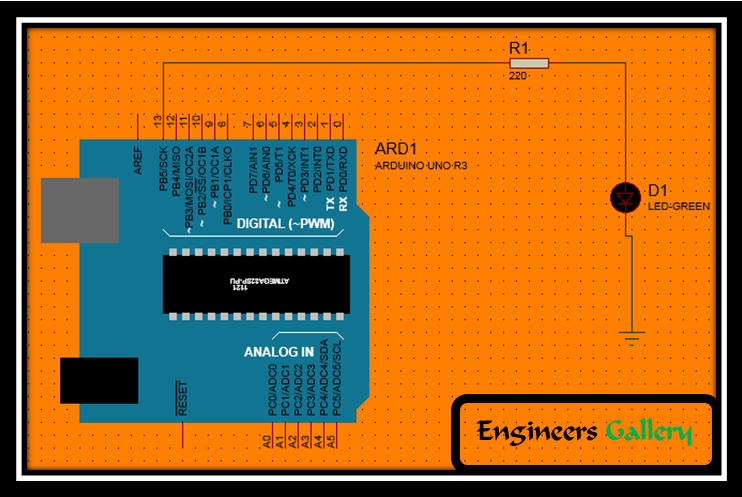

There is a third category possible between fixed automation and programmable automation that is called flexible automation using Computer Aided Design (CAD) and Computer Aided Manufacturing (CAD/CAM) activities. This is also called as flexible manufacturing system (FMS). It allows producing different products on the same equipment in any order or mix. One important example of programmable automation, in discrete manufacturing, is numerical control. Robot is another example of programmable automation. Robot being integral part of FMS and Computer Integrated Manufacturing (CIM) system can do a large number of manufacturing tasks for replacing the human labor.

In the present globalized manufacturing scenario, the advancements of hardware and software concepts using the mechatronics for fast mechanization and automation of manufacturing processes have become essential to be incorporated in the manufacturing areas.

Reference Introduction to basic Manufacturing Processes and Workshop Technology by Rajender Singh.

For engineering project visit this page regularly for know more things related project ideas. Click here to see Ideas of Projects.