Holding And Supporting Tools Used In Carpentary Shop

Sometimes it is desirable to support and gold a wooden board in a special manner while the work is being carried out. For these purposes, various supporting and holding devices are needed some of which are discussed as under.

Work Bench

Every carpenter generally needs a good solid bench or table of rigid construction of hard wood on which he can perform or carry out the carpentry operations. Work bench should be equipped with a vice for holding the work and with slots and holes for keeping the common hand tools. One jaw of the vice is tightened to the table and is kept moveable for holding the articles Work benches are built solidly with good heavy tops for providing a good working surface for cutting, as well. The vice on the bench is equipped with an adjustable dog that is, a piece of wood or metal can be moved up and down in the outside jaw of the vice.

Carpenter Vice

Carpenter vice is very important tool in wood working shops for holding wooden jobs. There are several varieties of vices, each possessing its own particular merit.

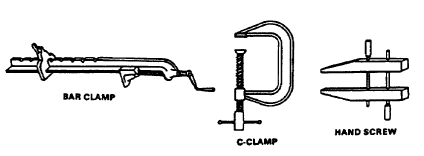

Clamp

Clamps are commonly used in pairs in gluing up operations at the final assembly of wood joinery work. These clamps can provide pressure required to hold joints together until they are secured due to the setting of glues. Clamps are of two types namely plain rectangular bar type and T-bar type. The former is made of mild steel and is usually rectangular in section.

The later may be of T-section, which can easily afford greater rigidity under stress. The coarse adjustment jaw may be located in any position on the bar by means of a steel pin which fits into any of the holes drilled at intervals along the bar. The fine adjustment jaw of the sash clamp is moved along the bar by a square threads screw which passes through a special nut fixed to the end of bar. Considerable pressure can be applied by turning the screw with the Tommy bar for holding a wooden job. Both jaws of the sash clamp are generally made of malleable cast iron which is tougher and less brittle than ordinary cast iron. There are other similar types of such clamps named as rack clamp, screw clamps, light duty parallel clamp, adjustable bar clamp, G or C-clamp, and double bar clamp which are useful for holding different sizes and shapes of wooden jobs. Copied from Basic of Manufacturing Processes and Workshop Technology by Rajender Singh.