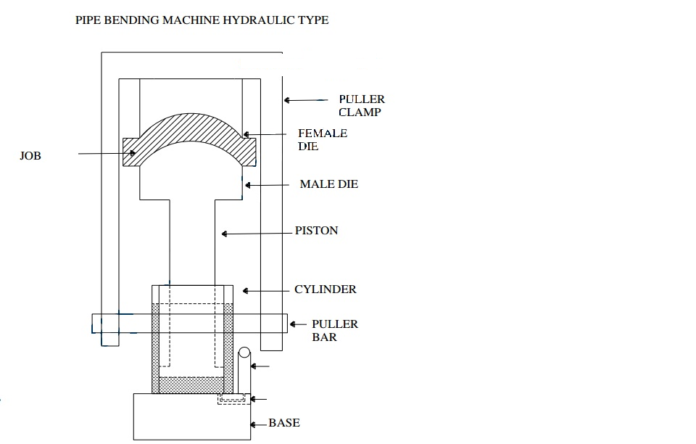

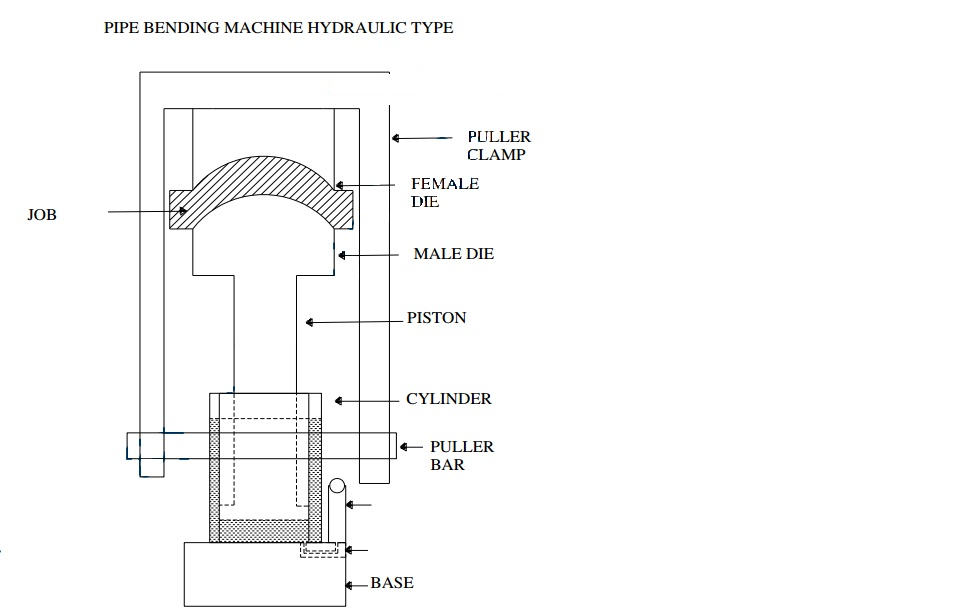

FABRICATION OF HYDRAULIC PIPE CLAMP PRESSING MACHINE

SYNOPSIS

Abstract:

A hydraulic fluid power system is defined as a means of power transmission in which relatively in-compressible fluid is used as the power transmitting media. The primary purpose of hydraulic system is the transfer of energy from one location to another location and this energy into useful work. In this project of the fabricated model of HYDRAULIC PIPE CLAMP PRESSING MACHINE is used to bend the pipe clamp and it will describe the working principles as well as hydraulic machines application and its advantages. Efforts have been taken to show the path of hydraulic fluid as it is applied and released.

The Hydraulic system pressure can be generated in the form of any physical action which result a compression over the Hydraulic system or pneumatic pressure which is developed in the form of air compressing externally can be applied to activate Hydraulic system. There is a constant relation between pressure density, and volume, According to Bernoulli’s equation. Liquids can be heated by applying high pressure without any external heat energy supplied to them. So the specific heat of any liquid system which is used in the hydraulic machinery must be more than enough to with stand the pressure applied over them also viscosity must be high enough for smooth conversion of external pressure applied over them to hydraulic pressure.

ADVANTAGES

1. It eliminates complicated parts like hydraulic cylinder pipe connections and pressure tubes.

2. Fluid Power transmitted through port so high efficient.

3. Control of system is easier

4. Maintenance cost is less

5. Can be achieved up to two ton force.

In this Hydraulic system lubricating system not necessary so that wear and tear very low.

APPLICATION

1. Engine recondition works

2. Pump assembling works

A/C and D/C Motor repair works