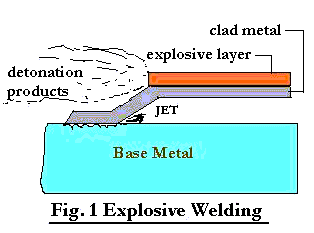

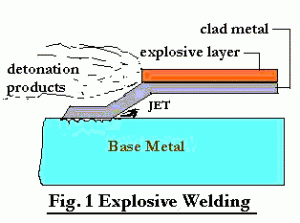

Explosive Welding

In explosive welding, strong metallurgical bonds can be produced between metal combinations which cannot be welded by other methods or processes. For example, tantalum can be explosively welded to steel although the welding point of tantalum is higher than the vaporization temperature of steel. Explosive welding process is shown in Fig. 1. It is carried out by bringing together properly paired metal surfaces with high relative velocity at a high pressure and a proper orientation to each other so that a large amount of plastic interaction occurs between the surfaces. The work piece, held fixed is called the target plate and the other called flyer plate. While a variety of procedures have been successfully employed, the main techniques of explosive welding can be divided into contact techniques and impact techniques. In critical space and nuclear application, explosive welding permits fabrication of structures that cannot be made by any other means and, in some commercial applications, explosive joining is the least costly method. The main advantage of explosive welding includes the simplicity of the process, and the extremely large surface that can be welded. Incompatible materials can also be bonded, and thin foils can be bonded to heavier plates. Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.