Bushed-pin Flexible Coupling

A bushed-pin flexible coupling, as shown in Fig. 1, is a modification of the rigid type of flange coupling. The coupling bolts are known as pins. The rubber or leather bushes are used over the pins. The two halves of the coupling are dissimilar in construction. A clearance of 5 mm is left between the face of the two halves of the coupling. There is no rigid connection between them and the drive takes place through the medium of the compressible rubber or leather bushes.

In designing the bushed-pin flexible coupling, the proportions of the rigid type flange coupling are modified. The main modification is to reduce the bearing pressure on the rubber or leather bushes and it should not exceed 0.5 N/mm2. In order to keep the low bearing pressure, the pitch circle diameter and the pin size is increased.

Let l = Length of bush in the flange,

d2 = Diameter of bush,

pb = Bearing pressure on the bush or pin,

n = Number of pins, and

D1 = Diameter of pitch circle of the pins.

We know that bearing load acting on each pin,

W = pb × d2 × l

∴ Total bearing load on the bush or pins

= W × n = pb × d2 × l × n

and the torque transmitted by the coupling,

T = W × n (D1/2) = pb × d2 × l × n (D1/2)

The threaded portion of the pin in the right hand flange should be a tapping fit in the coupling hole to avoid bending stresses.

The threaded length of the pin should be as small as possible so that the direct shear stress can be taken by the un-threaded neck.

Direct shear stress due to pure torsion in the coupling halves,

τ = W / {π/4 (d1)^2 }

Since the pin and the rubber or leather bush is not rigidly held in the left hand flange, therefore the tangential load (W) at the enlarged portion will exert a bending action on the pin as shown in Fig. 2. The bush portion of the pin acts as a cantilever beam of length l. Assuming a uniform distribution of the load W along the bush, the maximum bending moment on the pin,

M = W {(l/2) + 5 mm }

We know that bending stress,

σ = M / Z = W {(l/2) + 5 mm } / {π/32}(d1)^3

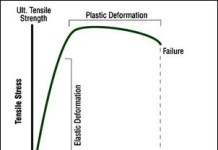

Since the pin is subjected to bending and shear stresses, therefore the design must be checked either for the maximum principal stress or maximum shear stress by the following relations :

(c) Friction joint bushing (d) Safety overload coupling.

Maximum principal stress

= 1/2 [ σ + {σ^2 + 4τ^2}^0.5]

and the maximum shear stress on the pin

= 1/2 {σ^2 + 4τ^2}^0.5

The value of maximum principal stress varies from 28 to 42 MPa.

Note: After designing the pins and rubber bush, the hub, key and flange may be designed in the similar way as discussed for flange coupling.

Reference A Textbook of a Machine Design by R. S. Khurmi and J. K. Gupta