AIR BRAKE

An air brake or, more formally, a compressed air brake system, is a type of friction brake for vehicles in which compressed air pressing on a piston is used to apply the pressure to the brake pad needed to stop the vehicle. Air brakes are used in large heavy vehicles, particularly those having multiple trailers which must be linked into the brake system, such as trucks, buses, trailers, and semi-trailers in addition to their use in railroad trains. George Westinghouse first developed air brakes for use in railway service. He patented a safer air brake on March 5, 1872. Westinghouse made numerous alterations to improve his air pressured brake invention, which led to various forms of the automatic brake. In the early 20th century, after its advantages were proven in railway use, it was adopted by manufacturers of trucks and heavy road vehicles.

A railway air brake is a power braking system with compressed air as the operating medium. Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on March 5, 1868. The Westinghouse Air Brake Company (WABCO) was subsequently organized to manufacture and sell Westinghouse’s invention. In various forms, it has been nearly universally adopted.

The Westinghouse system uses air pressure to charge air reservoirs (tanks) on each car. Full air pressure signals each car to release the brakes. A reduction or loss of air pressure signals each car to apply its brakes, using the compressed air in its reservoirs.

In aeronautics, air brakes or speed brakes are a type of flight control surface used on an aircraft to increase drag or increase the angle of approach during landing.

Related Articles

Braking System and Its Classification, Application, Advantages and Disadvantages

The earliest known air brake was developed in 1931 and deployed on the wing support struts. Not long after, air brakes located on the bottom of the wing’s trailing edge were developed and became the standard type of aircraft air brake for decades.

Air brakes differ from spoilers in that air brakes are designed to increase drag while making little change to lift, whereas spoilers reduce the lift-to-drag ratio and require a higher angle of attack to maintain lift, resulting in a higher stall speed.

In 1936, Hans Jacobs developed self-operating dive brakes, on the upper and lower surface of each wing, for gliders.Most early gliders were equipped with spoilers on the wings in order to adjust their angle of descent during approach to landing. More modern gliders use air brakes which may spoil lift as well as increase drag, dependent on where they are positioned.

Often, characteristics of both spoilers and air brakes are desirable and are combined – most modern airliner jets feature combined spoiler and air brake controls. On landing, the deployment of these spoilers (‘lift dumpers’) causes a dramatic loss of lift and hence the weight of the aircraft is transferred from the wings to the undercarriage, allowing the wheels to be mechanically braked with much less chance of skidding. In addition, the form drag created by the spoilers directly assists the braking effect. Reverse thrust is also used to help slow the aircraft after landing.

Air brake systems are the combination of three braking systems:

- The service brake system applies and releases the brakes when one uses the brake pedal during normal driving.

- The parking brake system applies and releases the parking brakes when one uses the parking brake control.

- The emergency brake system uses parts of the service and parking brake systems to stop the vehicle in the event of a brake system failure.

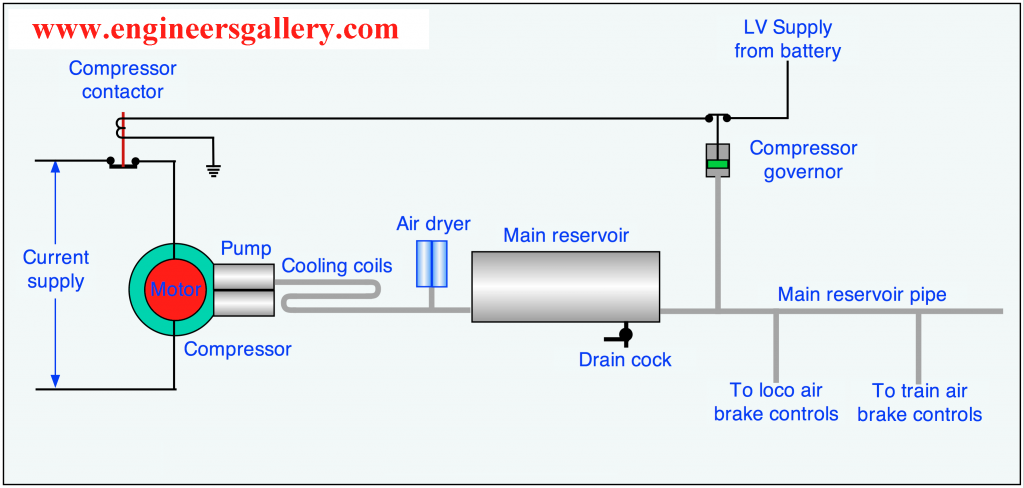

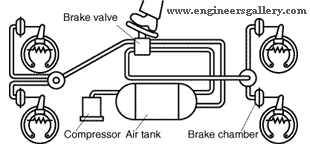

Working

Essentially, the air brake operates, at its most basic level, similar to the piston in an internal combustion engine would inside its cylinder. Air storage tanks are filled with compressed air by the compressor, which is powered by the engine. When the driver steps on the brake pedal, or treadle valve, this allows air from the storage tanks to flow into the cylinder, pushing the piston down the cylinder. This is the service portion of the system. This cylinder is called the brake chamber. The piston is attached to the push rod, which turns the slack adjuster. The slack adjuster connects the push rod to another rod, which then rotates. This rod is connected to the S-cam. There are several types of air brakes, including S-cam and wedge type brakes. The S-cam are the most widely used type. It is the S-cam that turns and pushes the brake shoes against the lining of the drum brake. The air brakes on a semi-trailer are connected to a tractor with two lines. One line is called the supply line or the emergency line. It is usually larger and is red or has red fittings. The emergency line provides air pressure to fill the semi-trailer’s reservoir tank and the pistons that activate the brakes. The other line is called the service line. It is usually smaller and is blue or has blue fittings. In normal braking, pressing the brake pedal pressurizes the service line. This activates a valve in the trailer which directs air from the reservoir and the emergency line to the brake cylinders where it moves the piston that activates the brakes. When the pedal is let up, the service line pressure is decreased. When the service line pressure drops, it causes the valve in the trailer to block the air supply from the reservoir while releasing the pressure in the brake cylinder and the brakes are released. The system is a form of servo or amplifier. If the pressure in the emergency line drops, due to the activation of a valve in the cab, the disconnection of the emergency line coupling, or a break in the emergency line, the spring brakes will come on, because there is no more air pressure in the trailer air tank to hold them back.

Advantages

Air brakes are used as an alternative to hydraulic brakes which are used on lighter vehicles such as automobiles. Hydraulic brakes use a liquid (hydraulic fluid) to transfer pressure from the brake pedal to the brake shoe to stop the vehicle. Air brakes have several advantages for large multitrailer vehicles:

- The supply of air is unlimited, so the brake system can never run out of its operating fluid, as hydraulic brakes can. Minor leaks do not result in brake failures.

- Air line couplings are easier to attach and detach than hydraulic lines; there is no danger of letting air into a pneumatic circuit. So air brake circuits of trailers can be attached and removed easily by operators with little training.

- Air not only serves as a fluid for transmission of force, but also stores potential energy. So it can serve to control the force applied. Air brake systems include an air tank that stores sufficient energy to stop the vehicle if the compressor fails.

- Air brakes are effective even with considerable leakage, so an air brake system can be designed with sufficient “fail-safe” capacity to stop the vehicle safely even when leaking.

Reference Wikipedia and easternmarine